Learning how to clean skateboard bearings is vitally important if you want to maintain the optimum quality of your bearings.

If you want to skateboard anywhere that has a bit of moisture or dirt, which is pretty much everywhere on the planet, and you don’t wish to buy bearings on a weekly basis it is worth knowing how to look after your bearings.

If you are running shieldless bearings then clean bearings ares even more important as the internal components are exposed to the elements.

It’s usually pretty easy to tell if your bearings need cleaning, visually they’ll look messy, but worst still, your board may become hard to handle because of dirty bearings and hurt your ability to shred some sick tricks!

Understanding the basics of bearings and why you need to keep them well maintained

Before we get into how to clean skateboard bearings, it’s worth having a whistle stop tour about how skate bearings are produced and some of the core components that are used to make them up.

The myth of skateboard ABEC ratings

The first thing we should clear up when talking about skate bearings is the myth about ABEC (Annular Bearing Economic Committee) ratings.

For years skaters have bought their bearings and assessed their quality by their ABEC rating.

I will now explain to you why the ABEC rating is a pointless way to assess bearing worth; it tells us nothing practical for skateboarding. So never ever pay extra for ABEC 7 over ABEC 5 or 3.

The difference in ABEC is tolerance; it goes from 1 to 9 in odd numbers. ABEC 9 is constructed with the tightest tolerances and 1 with the lowest. Now you are probably thinking I need ABEC 9 as they have the highest tolerance, they are obviously the best-manufactured version.

But all skate bearings have an 8mm bore, and we put them on a 5/16 of an inch axle. A 5/16 of an inch is 7.9375 mm, why then would you want an ABEC 9 over an ABEC 1 as you have lost the benefit of any tolerance straight away.

But does the precision not allow your bearings to spin faster? Yes, but when was the last time you rolled up to a ledge at 70mph and if you can carve a bowl at that speed kudos to you.

At the speeds you skateboard the difference between an ABEC 3 and an ABEC 7 is imperceptible. It’s not all about going fast. The ratings are for high-speed machinery, if you are running a factory you don’t want downtime caused by substandard bearings, but this is far less essential for a skateboard.

Races are important

Have you ever thought about the materials that are used in the construction of your bearings? You will find many bearings now come with a plastic style race; these are usually a nylon fiberglass composite construction. Are they the best for skateboarding? Probably not, if you talk to bearing engineers, they will recommend a style of chromium steel.

Why then do brands use nylon retainers? Your ball retainers are the most likely part of a bearing to rust, the balls and the raceways will be polished by skating and should stay rust free. As skateboarders we are highly unlikely to clean or lube their bearings, a steel race will rust giving the appearance of being of lower quality. So using a piece that does not cause rust we can be sure that our bearings will appear quality.

Axial vs radial

Your next issue is axial loads, side loads. ABEC does not test bearings for side loads; it tests them for radial loads. Radial testing is a forward and backward movement. You do this when you check your bearings by spinning them on the wheel. Spinning the wheel is not telling us much as we do not have the bearings loaded like when you are skating them. A well set up wheel and bearings will not spin forever when flicked; it will however massively outperform when getting used.

When you are out skating, you will be putting an axial load on your bearings. You will be doing this repeatedly and sometimes with a considerable amount of force. Even the humble powerslide here is testing your bearings, and your wheel will be flexing sideways above your bearings. With bearings made to a higher tolerance, this movement can be enough to kill them; lower tolerance bearings will live better through this abuse. Probably another reason why you don’t need ABEC 9 over ABEC3.

What can you use to clean skateboard bearings?

We recommend using 100% acetone or a specialist bearing degreaser to really lubricate them. It’s really all the bearings need for a proper clean.

But if you don’t have any of those items at hand, what else can you try? Well.. nothing really unless you want to ruin your bearings.

Can you use wd40 on skateboard bearings?

While technically there’s nothing stopping you from using WD40, we wouldn’t advise it!

You should not use WD40 to clean your skateboard bearings as this is not what that that product was designed for. WD 40 is an oil and water displacing spray, so while it might be OK at removing grit it’s not designed as a bearing lubricant.

You might find that it works initially, but it will likely negatively impact your bearings over time, causing damage and reducing their lifespan unnecessarily. WD to clean isn’t a great idea.

Can you clean skateboard bearings with rubbing alcohol?

Rubbing alcohol is usually an isopropryl alcohol or ethanol based liquid.

Isopropryl alcohol should be fine to clean your bearings, however you’ll want to make sure that the percentage is as close to 100% as possible, as weakened mixes containing water, could lead to your bearings rusting.

How to clean skateboard bearings

With that out of the way, we can get to the fun part, cleaning.

Cleaning your bearing with regular maintenance is a great way to extend their life.

Follow these simple steps to keep them in tip-top condition and avoid having to get your wallet out for replacements!

We’ll show you step by step how to properly clean your bearings.

First things first – Remove your dirty bearings

You’ll need to remove the bearings from your wheels, we’ve put together a handy tutorial on how to remove & install bearings which you may find useful.

You’ll need a few pieces of kit, but other than the cleaning solution, you should already have everything required without needing to buy any special equipment.

Step 1 – Preparation

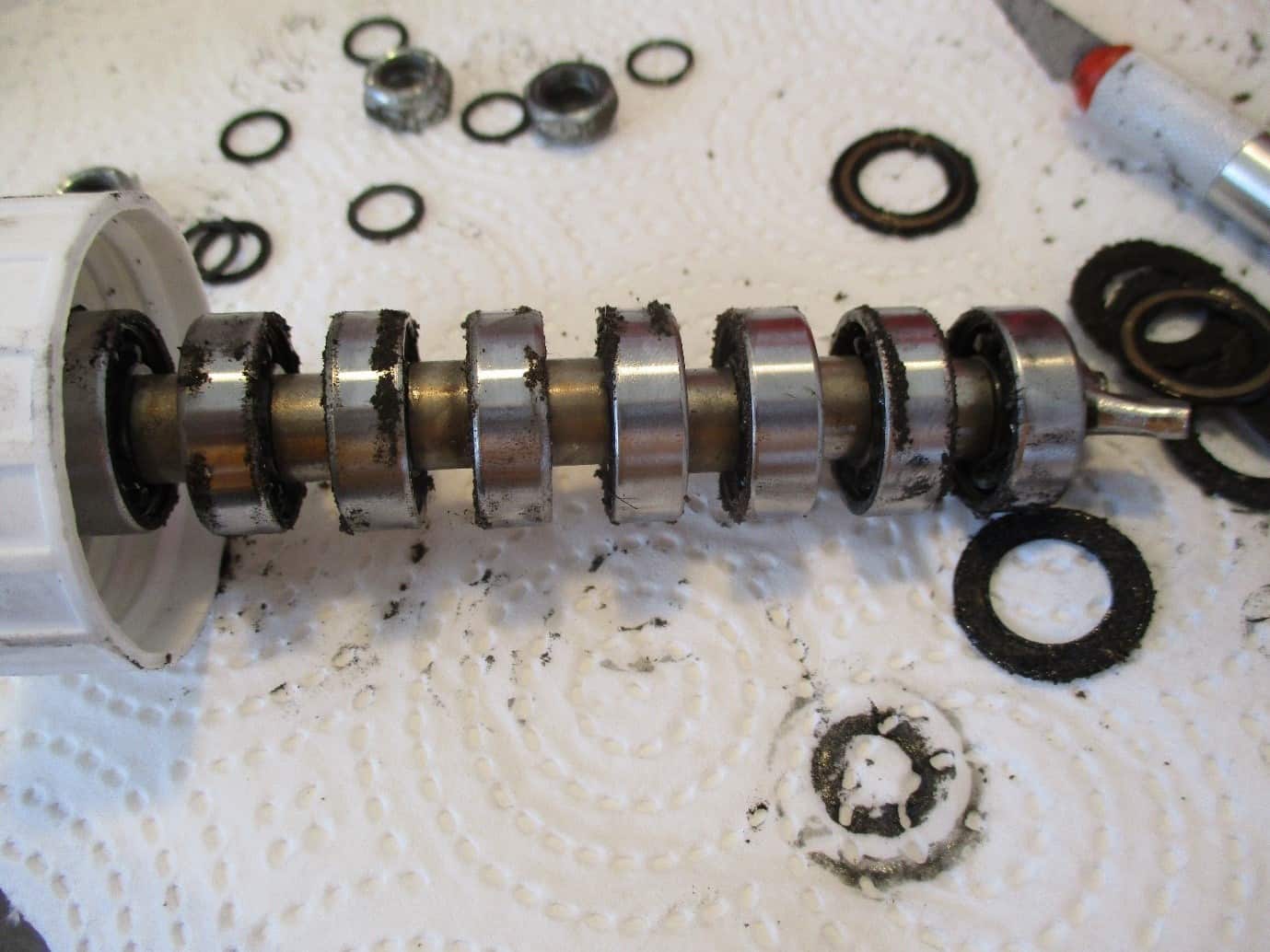

Once you’ve removed the bearings from the wheels, you’ll want to lay them down safely.

Grit can collect in your skateboard bearings along with all sorts of dust, mess and grime, so just be careful when cleaning them. We’d suggest laying them on a cloth or piece of kitchen towel.

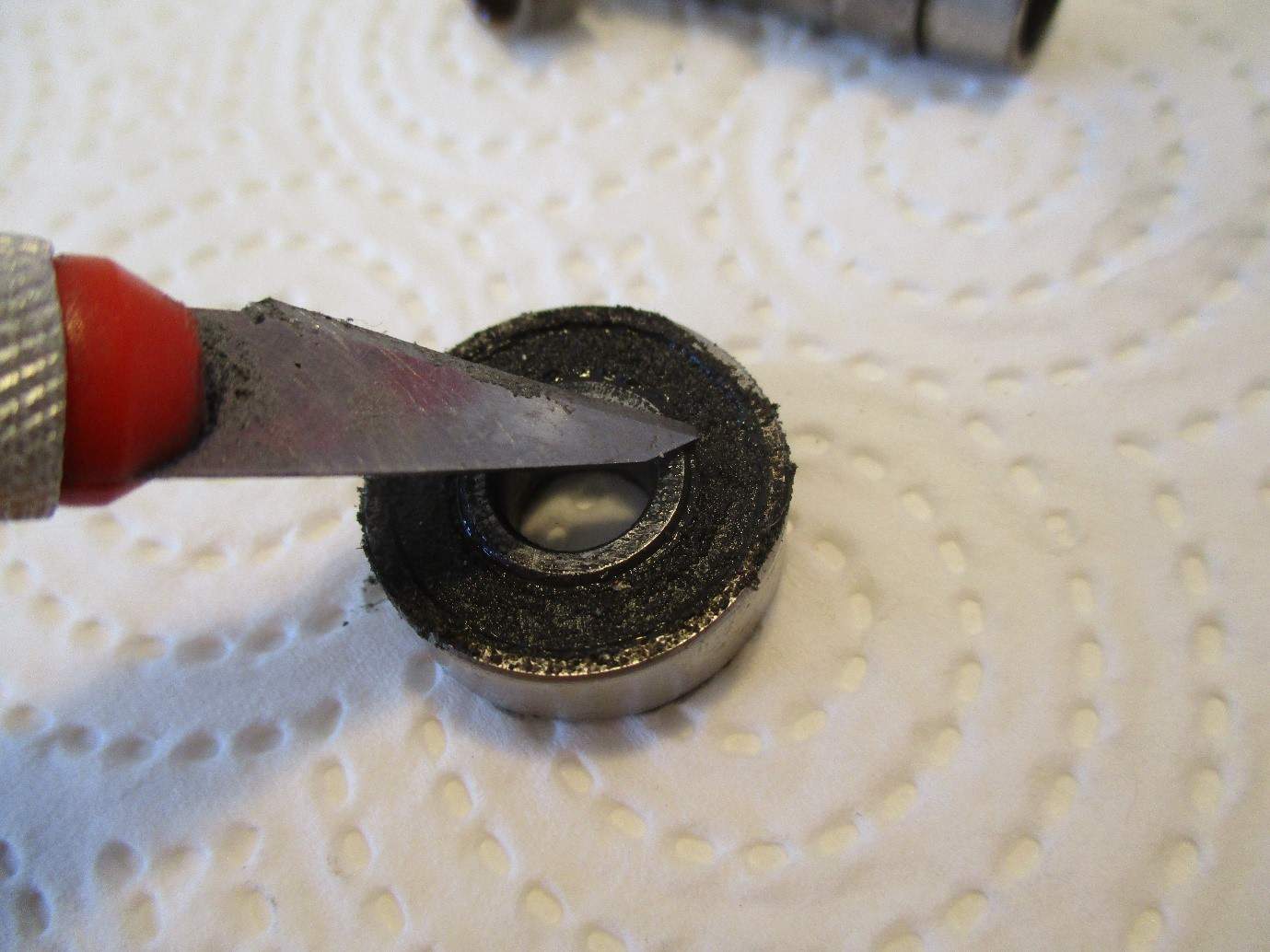

Step 2 – Poppin’ the seals

Now grab a thin flathead screwdriver or a small scalpel and pop the seals. You should be able to this by sliding the blade/tip in from the bore side and a small sideways movement should free the shield.

You should now have a bearing like this;

Step 3 – Soak them until clean

Now you can leave your bearings on a cloth and spray a solvent on them and make a complete mess.

Or, you can use a container and keep the house clean. Bones make a cool one;

With this Bones bearing cleaner tub you even get a nifty little bearing holder;

Pour in your cleaner, ideally 100% acetone or use a degreaser of some form;

Step 4 – Give em a shake

Shake your container (make sure you close the lid!);

The Bones skate bearings cleaning unit we use in this tutorial is optional, but definitely makers the process of cleaning your skate bearings easier and tidier.

Pull your bearings out and rinse them with Isopropyl alcohol, over 91%.

This is highly important, do not leave your bearings to air dry, they will rust.

This will also remove any residue left from cleaning.

Step 5 – Lube them up

Now lube them using a light oil of some form (you can buy skate specific bearing oil).

A couple of drops in each bearing should suffice;

Step 6 – Scrub up the shields

Give your shields a wipe down;

And watch as they magically change color!

Step 7 – Pop the shields back on

Then simply pop the shields back on, they should go back on easily with a little pressure;

All Done!

As I said looking after your skate bearings is not hard and if you take good care, your bearings should last years, not weeks.

This is something we should all aim for as it is a much more environmentally friendly and cost effective approach to keep your old bearings lasting longer.

Clean bearings not only ride better, they look better too, nobody looks cool rolling with dirty bearings spinning in their skateboard wheels.

How often should I clean my skateboard bearings?

Hopefully you now have a better understanding of how to clean skateboard bearings, and the importance of maintenance, but do you know how often to do so?

How often you should clean your skate bearings depends on a couple of things, primarily if mainly skate indoors or outdoors.

If you mainly skate indoors, your bearings are much less likely to require regular cleaning. In fact, you might get away with only having to clean them every couple of years..

However, if you do a lot of outdoor skating, especially in areas that are particularly dirty, or perhaps wet conditions, they you may find you need to give them a good clean every couple of months.

How do you clean your skateboard bearings?

Are we missing a top tip? Let us know in the comments below.